Add:No.52,Linyu Road,Nanbin Sub-district,Ruian City(Beside Linyang School)

Tel:0577-65590157

Fax:0577-65598286

Contact:Mr Jin

mobile phone:13806538205

QQ:494651928

Email:494651928@qq.com

site Url:www.65590157.com

| LM-300-XZH automatic paper box former |

|

LM-300-XZH automatic paper box former

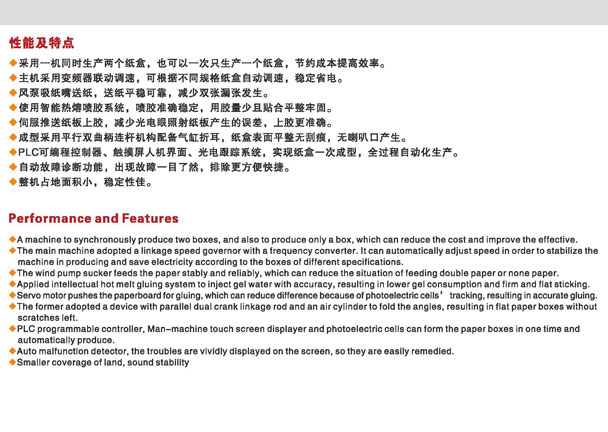

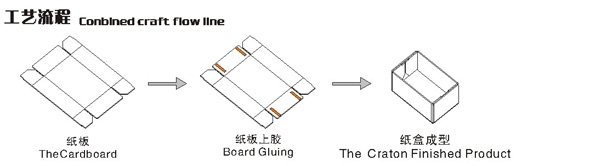

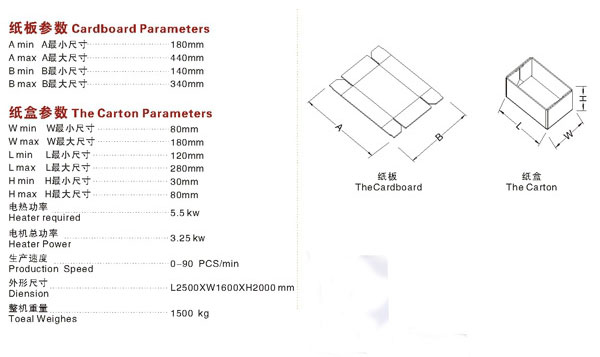

LM-300-XZH fully automatic paper box forming machine Performance and characteristics: The LM-300-XZH paper box forming machine is a self developed adhesive paper box packaging equipment by our factory. Mainly used for the production and processing of small adhesive paper box packaging, it is widely used in the handicrafts, electronics, electrical appliances, hardware, and standard parts world cover paper box packaging industry. PLC programmable controller, photoelectric tracking system, touch screen human-machine interface, the host is equipped with frequency converter speed regulation, combined with servo motor paper feeding mechanism, air pump suction nozzle paper feeding mechanism, intelligent hot melt adhesive spraying system and other systems to complete paper feeding, gluing, and forming in one go. Adopting the method of producing two cardboard boxes simultaneously on one machine can save costs and improve efficiency, making it the preferred equipment for current letter box packaging enterprises. Product Introduction: By using a single machine to produce two paper boxes simultaneously, it is also possible to produce only one paper box at a time, saving costs and improving efficiency. The host adopts a frequency converter linkage speed regulation, which can automatically adjust the speed according to different specifications of paper boxes, ensuring stable and energy-saving. The air pump suction nozzle delivers paper smoothly and reliably, reducing the occurrence of double sheet leakage. Using an intelligent hot melt glue spraying system, the glue spraying is accurate and stable, with a small amount of glue used and a smooth and firm adhesion. Servo push of cardboard gluing reduces the error caused by photoelectric eye irradiation on the cardboard, resulting in more accurate gluing. The molding adopts a parallel double crank connecting rod mechanism equipped with cylinder folding ears, and the surface of the paper box is flat without scratches or horns. PLC programmable controller, touch screen human-machine interface, photoelectric tracking system, realizing one-time molding of paper boxes and full process automation production. The automatic fault diagnosis function makes it clear at a glance when faults occur, making troubleshooting more convenient and efficient. The whole machine has a small footprint and good stability.

|

Mr Jin

Mr Jin